Introduction

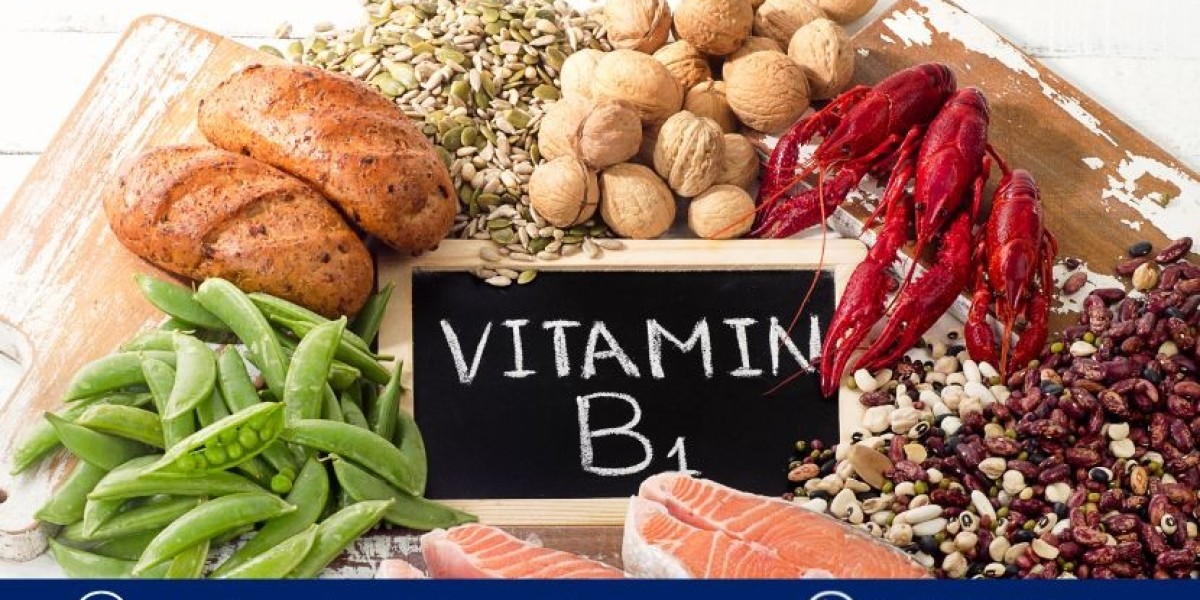

Vitamin B1, also known as thiamine, plays a crucial role in maintaining healthy metabolism and nervous system function. As a vital water-soluble vitamin, it is an essential nutrient that is found in various food sources such as whole grains, pork, and legumes. However, due to dietary restrictions or insufficient intake, people around the world often require supplements to meet their daily Vitamin B1 needs. This has led to a growing market for Vitamin B1 supplements, particularly in the food, pharmaceutical, and animal feed industries. A Vitamin B1 Manufacturing Plant Project Report is essential for entrepreneurs or businesses looking to establish or scale up production in this lucrative market. This report provides a comprehensive guide to setting up a Vitamin B1 production facility, from raw material sourcing and manufacturing processes to financial projections and market analysis. With increasing awareness about the importance of vitamins in daily nutrition and health, the Vitamin B1 manufacturing industry presents significant opportunities for growth and profitability.

Market Demand for Vitamin B1

The global demand for Vitamin B1 has increased due to its widespread use in dietary supplements, functional foods, pharmaceuticals, and animal feed. The growing awareness about the importance of a balanced diet and the rising incidence of vitamin deficiencies across different age groups has further fueled the demand for Vitamin B1 supplements.

Some key drivers contributing to the growth of the Vitamin B1 market include:

Health Awareness: Increased consumer awareness about the importance of vitamins in maintaining overall health.

Rising Health Conditions: The growing incidence of conditions like malnutrition, gastrointestinal disorders, and fatigue, where Vitamin B1 deficiency is common.

Demand for Fortified Foods: The increasing popularity of fortified foods and beverages in both developed and developing countries.

Animal Feed Industry: Vitamin B1 is essential for animal health, and its inclusion in livestock and poultry feed has also contributed to market growth.

Get a Free Sample Report with Table of Contents@

Industry Overview

Global Vitamin B1 Market Trends

The global Vitamin B1 market has witnessed steady growth over the past few years, with significant demand from regions like North America, Europe, and Asia-Pacific. The increasing focus on nutrition and wellness, along with the rising prevalence of diseases related to Vitamin B1 deficiency, such as beriberi, has contributed to the increased consumption of Vitamin B1 supplements.

In emerging economies like India, China, and Brazil, the demand for Vitamin B1 is on the rise due to growing awareness of its health benefits and the increasing middle-class population that can afford dietary supplements.

Applications of Vitamin B1

Vitamin B1 is widely used across multiple industries, making it a versatile ingredient. The major applications of Vitamin B1 include:

Pharmaceutical Industry: Vitamin B1 is a key component in the production of tablets, capsules, and injectable formulations for treating deficiencies.

Food and Beverage Industry: It is often used as a food additive in fortified foods, energy drinks, and nutritional products.

Animal Feed Industry: It is added to livestock and poultry feed to ensure optimal growth and health of animals.

Cosmetics and Personal Care: Vitamin B1 is used in cosmetic products for its antioxidant properties, which help improve skin health.

Vitamin B1 Manufacturing Process

The manufacturing process of Vitamin B1 involves several chemical and biological processes. Understanding the steps involved is essential for setting up a cost-effective and high-quality production facility.

1. Raw Material Sourcing

The primary raw materials for Vitamin B1 production are thiamine derivatives, typically thiamine hydrochloride or thiamine mononitrate. These derivatives are sourced from specialized chemical suppliers who provide the raw ingredients for Vitamin B1 synthesis.

Thiamine Derivatives: The main precursor used in the production of Vitamin B1 is thiamine salt. The salt is further processed to produce the pure form of Vitamin B1.

Solvents and Reagents: Solvents and other reagents are used in the synthesis process to convert the raw materials into the final Vitamin B1 product.

2. Synthesis and Chemical Reactions

The synthesis of Vitamin B1 is carried out through a complex chemical reaction. The most commonly used method for Vitamin B1 synthesis is the biosynthetic method, which involves fermenting thiamine salts to produce high-purity Vitamin B1. The basic steps include:

Synthesis of Thiamine Derivatives: Thiamine derivatives are synthesized through a multi-step chemical process involving the reaction of various chemical agents and substrates.

Purification: After synthesis, the crude product is purified using distillation, crystallization, or filtration techniques to remove impurities and obtain high-quality Vitamin B1.

Drying: The purified Vitamin B1 is then dried to remove excess moisture, ensuring that it is stable and suitable for storage.

3. Formulation and Standardization

Once the Vitamin B1 has been synthesized and purified, it is standardized to ensure that each batch meets the required specifications. The final product is then mixed with other excipients, such as binders or stabilizers, to ensure proper delivery and effectiveness when used in supplements or fortified foods.

4. Quality Control

Quality control is a critical part of the manufacturing process to ensure that the Vitamin B1 produced meets all safety, purity, and efficacy standards. Testing is performed at various stages of the production process, including raw material inspection, intermediate testing during synthesis, and final product testing. Some common tests include:

Purity and Potency: Ensuring the correct concentration of Vitamin B1.

Microbial Testing: To ensure the product is free from harmful microorganisms.

Stability Tests: To confirm that the Vitamin B1 remains stable over time under various storage conditions.

5. Packaging and Distribution

After quality control checks, the final Vitamin B1 product is packaged in suitable containers such as bottles, blister packs, or bulk containers, depending on the target market. The packaging should be airtight and moisture-proof to preserve the potency of Vitamin B1. The product is then ready for distribution to pharmaceutical companies, food manufacturers, and other customers.

Plant Setup and Investment

Location Selection

The location of a Vitamin B1 manufacturing plant is essential for ensuring smooth operations and minimizing costs. Factors to consider include:

Proximity to Raw Material Suppliers: Being close to chemical suppliers can reduce transportation costs for raw materials.

Access to Skilled Labor: The plant should be located in an area with access to skilled workers, particularly those with experience in the chemical or pharmaceutical industries.

Infrastructure: Ensure that the plant is located near transportation hubs, such as highways, ports, or airports, for efficient distribution.

Equipment and Machinery

To set up a Vitamin B1 manufacturing plant, several pieces of specialized equipment and machinery are needed:

Fermentation Reactors: Used in the synthesis of thiamine derivatives.

Crystallization and Filtration Units: For purifying the synthesized Vitamin B1.

Dryers: To remove moisture and preserve the product.

Mixing and Blending Equipment: For formulating and standardizing the Vitamin B1 product.

Initial Investment and Operational Costs

Setting up a Vitamin B1 manufacturing plant requires a significant initial investment. The costs associated with plant setup include:

Land and Building Costs: The cost of acquiring land and constructing the plant.

Machinery and Equipment: Investment in specialized equipment for synthesis, purification, and packaging.

Raw Material Procurement: The cost of thiamine derivatives and other chemicals.

Labor and Operational Costs: Wages, utilities, and other ongoing operational expenses.

Regulatory Compliance

Manufacturers of Vitamin B1 must adhere to strict regulatory standards. Depending on the region, regulatory bodies such as the FDA (U.S.), EFSA (Europe), or APVMA (Australia) provide guidelines that must be followed. Compliance with these regulations ensures that the Vitamin B1 produced is safe, effective, and suitable for use in supplements and fortified foods.

Financial Projections and Market Analysis

A Vitamin B1 Manufacturing Plant Project Report should include detailed financial projections, including capital investment, expected revenue, operational costs, and profitability. This will help investors assess the viability of the plant and its long-term growth potential.

Key components of the financial model should include:

Initial Capital Expenditure: The upfront investment required to set up the plant.

Operating Expenses: Ongoing costs such as labor, utilities, raw materials, and maintenance.

Revenue Projections: Based on estimated sales, product pricing, and market demand.

Return on Investment (ROI): Analysis of the expected return over time.